Electrical

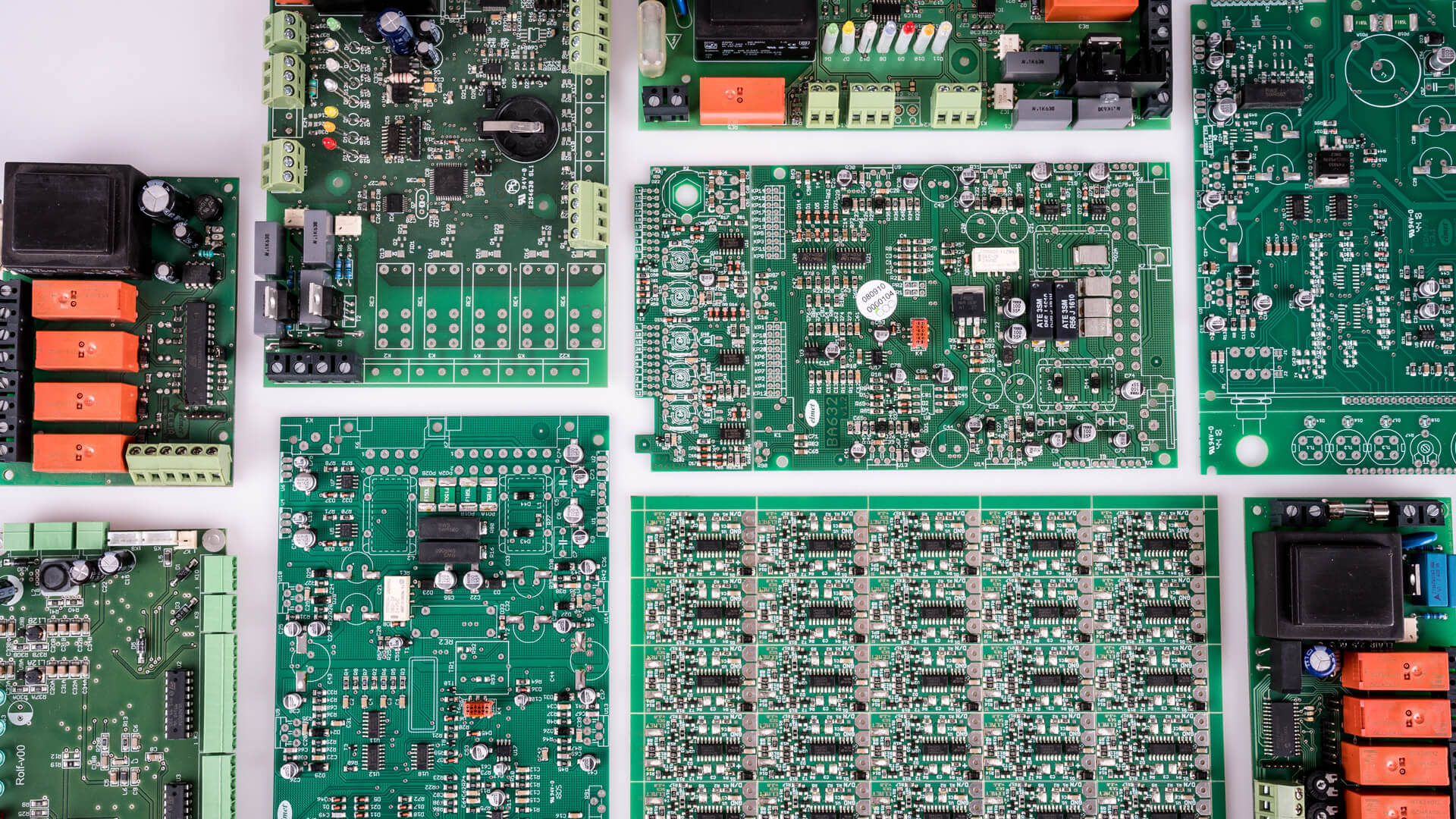

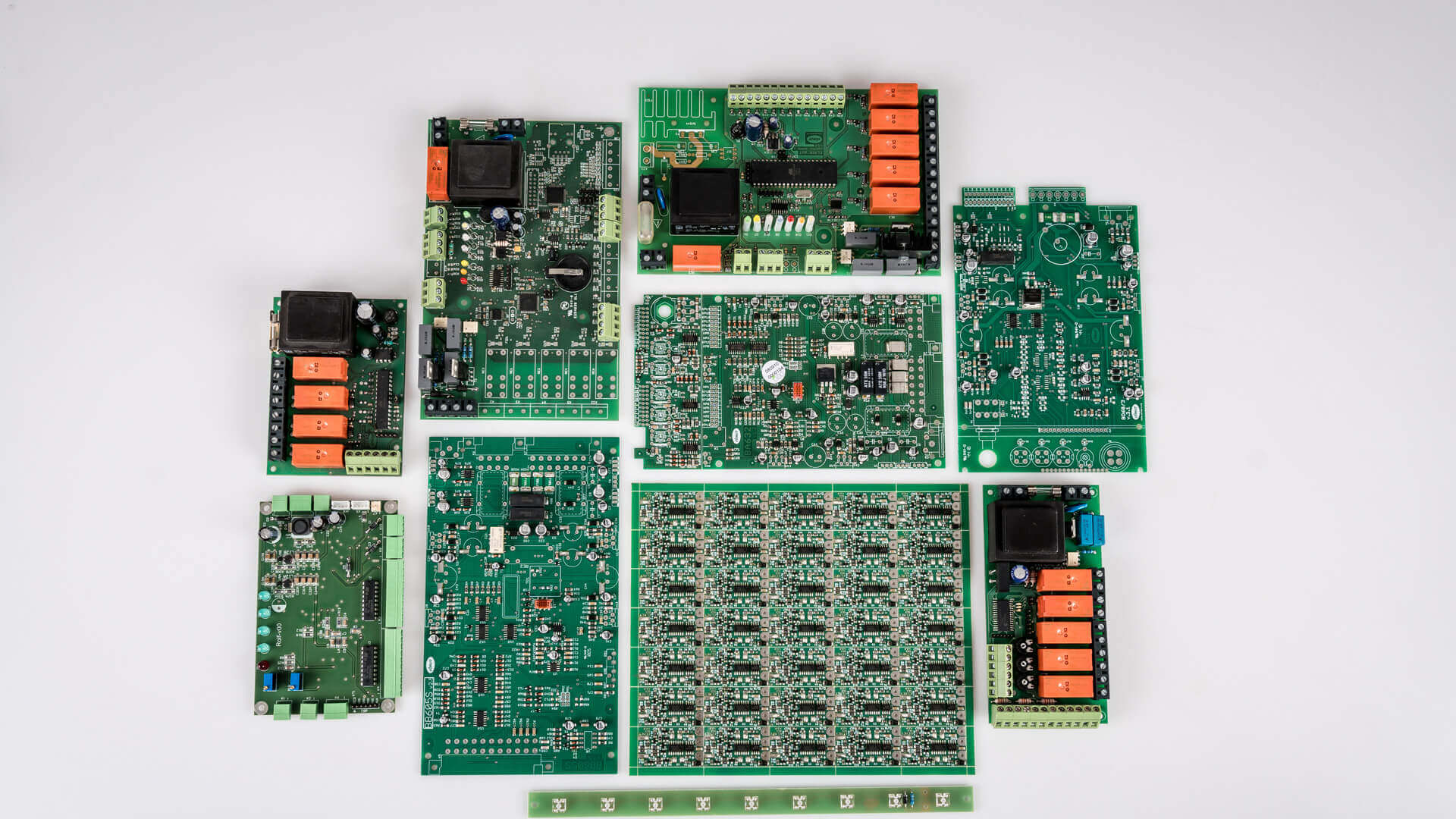

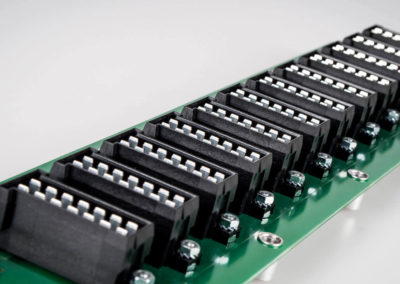

We offer high-capacity PCB mounting on our modern lines. The lines are fully automated, allowing for THT mounting and final assembly of your products.

We are ready to use our advanced technologies to deliver: from single pieces to small and large scale production, according to your documentation. Development and production of samples. Source documentation for manufacture and assembly.

Mounting lines with automatic DPS technology, automatic print of paste solder with immediate quality test at checkpoints, mounting automatons for most existing types of SMD parts including connectors, soldering ovens with temperature profile settings and active cooling, automated optical testers Mirtec and Göpel checking the mounting quality, position and polarity of parts, soldering quality, laser measuring of height (Mirtec).

Custom-made:

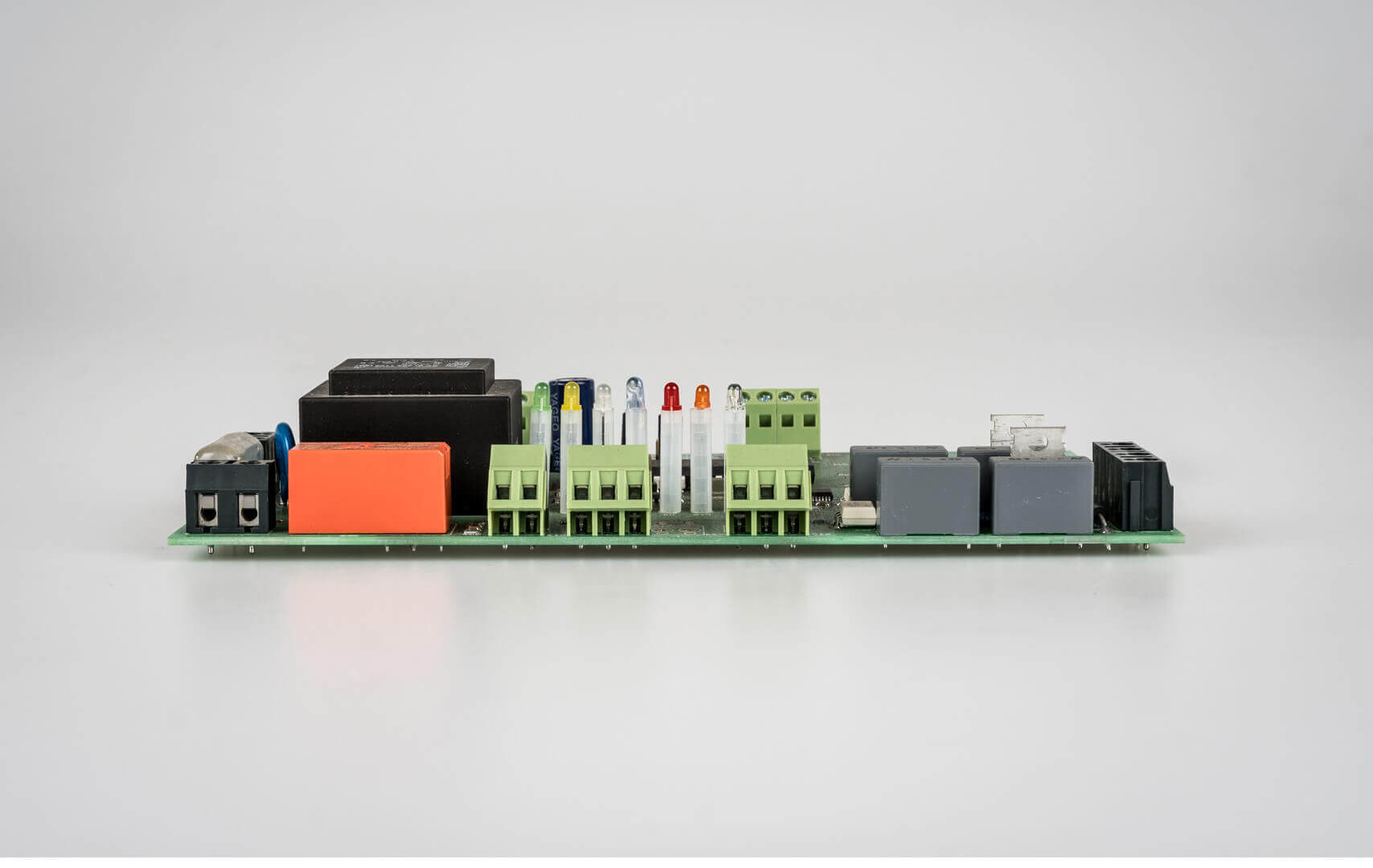

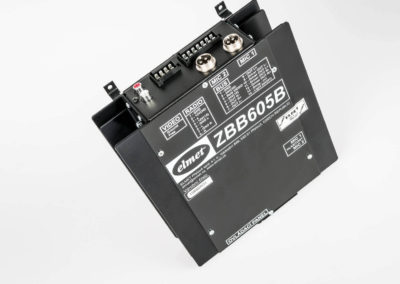

- Audio equipment and accessories for buses, including spare parts

- SMT and THT mounting on YAMAHA and MYDATA lines, including materials and source documents

- Design and development

- Assembly and installation

Final production:

- High-performance amplifiers, audio mixers etc.

- Multi-media panels.

The services provided may also include:

- Manufacture of both mounted and non-mounted DPS

- Development of drawings and blueprints

- Manufacture of mechanic parts

- Completion of boards with mechanic parts and manual finish

- Final operations, including inspection and packing

- Turnkey production (OEM).

Automated mounting

Technical mounting possibilities – “YAMAHA” line:

Mounting capacity: up to 30,000 SMD parts/hr (according to IPC9850).

Throughput: Up to 100,0000 boards/month (depending on DPS size, number and type of SMD parts on PCB).

Board size: PCB min 50×50 mm – max.450×400 mm.

Precision: 0.05 mm/chip (QFP).

Dimensions of parts: from 0201 type to 32×32 mm, casing height max. 15 mm.

Number of positions – 8 mm: 96.

Chips/casings: normally used types

Technical mounting possibilities – “MYDATA” line:

Mounting capacity: up to 30,000 SMD parts/hr (according to IPC9850).

Throughput: up to 100,000 mounted boards/month.

Board size: PCB min 50×50 mm – max.450×400 mm.

Precision: XY axis 15 µm/ 3 sigma.

Dimensions of parts: 0.6×0.6×0.25 up to 56 x 56 x 15 mm.

Number of positions – 8 mm: 144.

Chips: 0402 and bigger, casings SOIC, PLCC, TSOP, QFP, BGA, flip chip, CSP, SMD connectors etc.

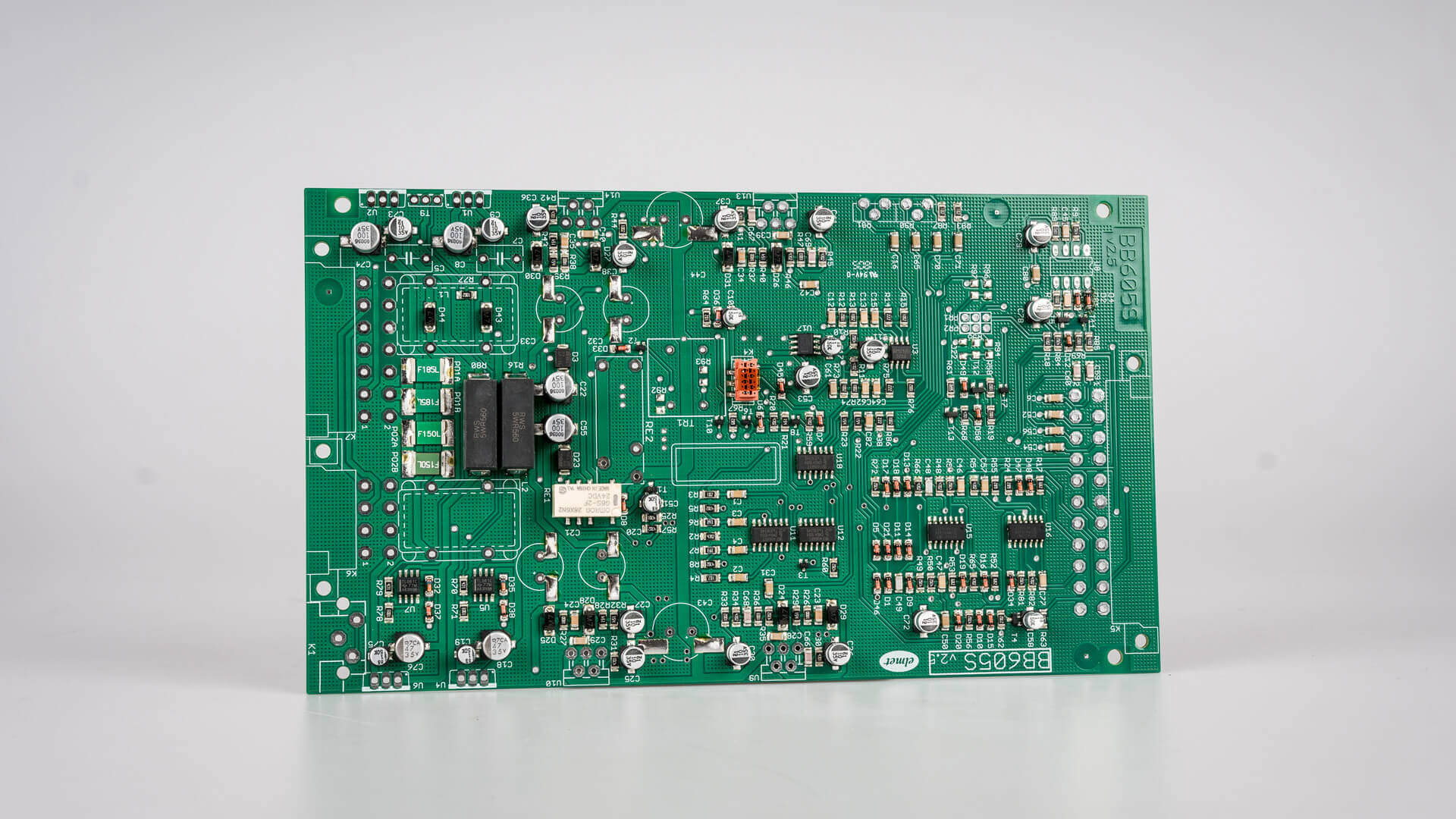

Completion of products:

We perform complete assembly of mounted boards, PCBs into the final product, according to the customer’s requirements, including chip programming, initiation, functional tests of the whole product, trial operation, final check, packaging and transport.

Custom design and development:

- Electronic devices and systems, drawings and regulations

- Manufacture of mechanical parts for final assembly, including the boxes, front panels, printing, labelling and packaging (blisters).

- Turnkey production (OEM).

- Printed circuit design and manufacture

- Source documents from data supplied (Gerber data)

- Development and manufacture of prototypes, functional models and samples

Contact

ELMET, spol. s r.o.

Nádražní 889, 535 01 Přelouč

The Czech Republic

ID: 42936349

VAT ID: CZ 42936349